A Robbins medallion is a personal memento made exclusively for the NASA astronaut. They are made by the Robbins Company, located in Attleboro, Massachusetts.

Astronauts who are in line for a flight, have the option of purchasing the medallions for themselves, family, and friends, as personal souvenirs. The medallions are made available only to the astronauts, no one else. They can either purchase a sterling silver medallion, or a 10k gold medallion. Gold medallions are far more expensive to purchase, thus their production numbers are much, much lower. Total production numbers vary for each mission. Silver medallions usually average somewhere around 150, while the Gold medallions average around 5.

At the conclusion of an astronauts flight, the medallions are sent back to Robbins, where they are engraved with the launch and landing dates on the back, polished, numbered, then returned to the astronauts. The dyes are later destroyed, and no more are ever remade. To date, only 3 medallions have ever been restruck: STS-51L, STS-107, and Expedition 7.

Regardless if they are flown or not, the low production numbers make them extremely desirable to space memorabilia collectors.

Astronauts who are in line for a flight, have the option of purchasing the medallions for themselves, family, and friends, as personal souvenirs. The medallions are made available only to the astronauts, no one else. They can either purchase a sterling silver medallion, or a 10k gold medallion. Gold medallions are far more expensive to purchase, thus their production numbers are much, much lower. Total production numbers vary for each mission. Silver medallions usually average somewhere around 150, while the Gold medallions average around 5.

At the conclusion of an astronauts flight, the medallions are sent back to Robbins, where they are engraved with the launch and landing dates on the back, polished, numbered, then returned to the astronauts. The dyes are later destroyed, and no more are ever remade. To date, only 3 medallions have ever been restruck: STS-51L, STS-107, and Expedition 7.

Regardless if they are flown or not, the low production numbers make them extremely desirable to space memorabilia collectors.

NASA Medallions/Coins - Dies & Cutters

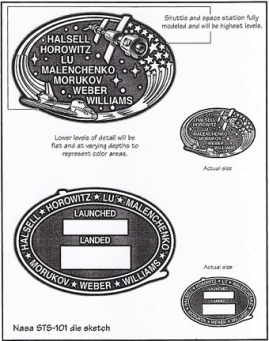

For the NASA medallions/coins, our job is to reproduce in metal, the medallion / coin-sized versions of the patch designs for the Shuttle, and now, Expedition missions. Our design department takes a NASA mission patch, and then "interprets" it from the viewpoint of a toolmaker/die cutter who must hand cut - design in reverse - the dies that are subsequently used to strike blank pieces of relatively thick (0.101") metal. The amount of detail, the height of lettering, the areas that are to be polished, the areas that are to be oxidized (we call it coloring or shading), the areas that are to be textured, the overall shape of the design with respect to fitting it to the plastic holder box, the final projected weight of the medallion / coin, etc., etc., etc. are all factors that we must consider and deal with. In addition we must create the design, and make the die, for the back or reverse of the medallion / coin, leaving the blank rectangular fields that take the engraved dates of launch and landing.

In terms of time frames we work backwards from the expected launch date of a given mission. Struck, unfinished medallions / coins must be in NASA's hands 30 days prior to launch. In order to satisfy this requirement we need to have the final, approved design in our possession 75 days (2 1/2 months) prior to launch (give or take a few days). We receive the design, produce the die cutter sketches (obverse and reverse), produce the dies and cutter (note if the design is not perfectly round, we must create a custom cutter tool in the shape of the design - a cutter is used to remove the excess metal squeezed out in the striking process), strike the medallions / coins, and then ship them to NASA. The most time consuming process is producing the dies and cutter, hence the long lead-time. As one might appreciate, one wrong slip of the die cutter's handtool can send us back to square one (and, yes, this has happened).

For the NASA medallions/coins, our job is to reproduce in metal, the medallion / coin-sized versions of the patch designs for the Shuttle, and now, Expedition missions. Our design department takes a NASA mission patch, and then "interprets" it from the viewpoint of a toolmaker/die cutter who must hand cut - design in reverse - the dies that are subsequently used to strike blank pieces of relatively thick (0.101") metal. The amount of detail, the height of lettering, the areas that are to be polished, the areas that are to be oxidized (we call it coloring or shading), the areas that are to be textured, the overall shape of the design with respect to fitting it to the plastic holder box, the final projected weight of the medallion / coin, etc., etc., etc. are all factors that we must consider and deal with. In addition we must create the design, and make the die, for the back or reverse of the medallion / coin, leaving the blank rectangular fields that take the engraved dates of launch and landing.

In terms of time frames we work backwards from the expected launch date of a given mission. Struck, unfinished medallions / coins must be in NASA's hands 30 days prior to launch. In order to satisfy this requirement we need to have the final, approved design in our possession 75 days (2 1/2 months) prior to launch (give or take a few days). We receive the design, produce the die cutter sketches (obverse and reverse), produce the dies and cutter (note if the design is not perfectly round, we must create a custom cutter tool in the shape of the design - a cutter is used to remove the excess metal squeezed out in the striking process), strike the medallions / coins, and then ship them to NASA. The most time consuming process is producing the dies and cutter, hence the long lead-time. As one might appreciate, one wrong slip of the die cutter's handtool can send us back to square one (and, yes, this has happened).

The two types of metal used for NASA coins/medallions are Sterling Silver and 10k Gold.

Often incorrectly referred to as solid silver, Sterling Silver is composed of 925 parts of pure silver and 75 parts alloy, usually Copper. In England, 925 is always called silver, not sterling. Each Sterling piece should show a "Sterling mark".

The word "Sterling" is the best known and most respected marking in use today. Pure silver alone is too soft for everyday use. Copper is the metal commonly used to give "Sterling" its added stiffness and wearing qualities. Sterling is often referred to as solid silver. It is composed of 925 parts pure silver in every 1000 - this proportion never varies - it is fixed by law.

Karat is a measure of the fineness of gold, 24 karat gold is pure gold. 18 karat gold is 18/24 gold (about 75% gold - three quarters gold). 14 karat gold is 14/24 gold (about 58% gold - a little over half gold). 12 karat gold is exactly half gold. 10 karat gold is 10/24 gold (only about 43.5% gold - less than half gold).

The method by which fineness of gold is expressed. Pure unalloyed gold is 24 karat. As an alloy metal is added (usually Copper), the karat value declines: 22k, 20k, 18k, and so on. The lowest grade of gold to carry a karat mark in the United States is 10k, or, in Great Britain, 9k. Most gold coins are 20k or 21k. Jewelry is commonly 9k to 18k. The word karat derives from the carob bean, used as a measure of weight in the ancient world. When spelled "carat", it refers to the weight of a precious gem and has nothing to do with the fineness of a metal in the United States.

Often incorrectly referred to as solid silver, Sterling Silver is composed of 925 parts of pure silver and 75 parts alloy, usually Copper. In England, 925 is always called silver, not sterling. Each Sterling piece should show a "Sterling mark".

The word "Sterling" is the best known and most respected marking in use today. Pure silver alone is too soft for everyday use. Copper is the metal commonly used to give "Sterling" its added stiffness and wearing qualities. Sterling is often referred to as solid silver. It is composed of 925 parts pure silver in every 1000 - this proportion never varies - it is fixed by law.

Karat is a measure of the fineness of gold, 24 karat gold is pure gold. 18 karat gold is 18/24 gold (about 75% gold - three quarters gold). 14 karat gold is 14/24 gold (about 58% gold - a little over half gold). 12 karat gold is exactly half gold. 10 karat gold is 10/24 gold (only about 43.5% gold - less than half gold).

The method by which fineness of gold is expressed. Pure unalloyed gold is 24 karat. As an alloy metal is added (usually Copper), the karat value declines: 22k, 20k, 18k, and so on. The lowest grade of gold to carry a karat mark in the United States is 10k, or, in Great Britain, 9k. Most gold coins are 20k or 21k. Jewelry is commonly 9k to 18k. The word karat derives from the carob bean, used as a measure of weight in the ancient world. When spelled "carat", it refers to the weight of a precious gem and has nothing to do with the fineness of a metal in the United States.

Pictured below is one of the original Expedition 7 Silver Robbins Medallions that was minted for the ISS crew. It was not noted until after the original distribution of medallions had gone out, that the wrong Cosmonauts name had been struck on the medallion. The name reads, S. Moschenko ( Sergei Ivanovich Moschenko ) . The correct name should be Y. Malenchenko ( Yuri Ivanovich Malenchenko ) .

Once the error was discovered, Robbins sent out a letter asking that the medallions be returned to the company so that they could be destroyed. Replacement medallions with the correct name on them were then minted and returned to the astronauts.

|

Mission

STS-1 STS-2 STS-3 STS-4 STS-5 STS-6 STS-7 STS-8 STS-9 STS-41B STS-41C STS-41D STS-41G STS-51A STS-51C STS-51D STS-51B STS-51G STS-51F STS-51I STS-51J STS-61A STS-61B STS-61C STS-51L STS-26 STS-27 STS-29 STS-30 STS-28 STS-34 STS-33 STS-32 STS-36 STS-31 STS-41 STS-38 STS-35 STS-37 STS-39 STS-40 STS-43 STS-48 STS-44 STS-42 STS-45 STS-49 STS-50 STS-46 STS-47 STS-52 STS-53 STS-54 STS-56 STS-55 STS-57 STS-51 STS-58 STS-61 STS-60 STS-62 STS-59 STS-65 STS-64 STS-68 STS-66 STS-63 STS-67 STS-71 STS-70 STS-69 STS-73 STS-74 STS-72 STS-75 STS-76 STS-77 STS-78 STS-79 STS-80 STS-81 STS-82 STS-83 STS-84 STS-94 STS-85 STS-86 STS-87 STS-89 STS-90 STS-91 STS-95 STS-88 STS-96 STS-93 STS-103 STS-99 STS-101 STS-106 STS-92 STS-97 STS-98 STS-102 STS-100 STS-104 STS-105 STS-108 STS-109 STS-110 STS-111 STS-112 STS-113 STS-107 STS-114 EXP 1 EXP 2 EXP 3 EXP 4 EXP 5 EXP 6 EXP 7 EXP 8 EXP 9 EXP 10 |

Gold Flown

24 1 2 2 4 7 13 8 5 8 1 8 8 13 9 12 19 10 5 10 9 15 7 7 6 5 1 7 2 0 1 2 2 6 2 7 8 5 8 6 1 2 4 6 4 0 4 6 21 10 6 7 0 6 3 0 6 6 6 2 7 5 4 3 2 1 9 8 1 5 3 1 0 9 6 6 2 3 4 2 6 3 1 4 5 1 7 7 4 4 14 3 6 0 2 7 4 3 2 0 3 1 1 6 7 3 1 6 0 2 0 0 1 0 0 1 0 |

Gold Unflown

10 18 11 11 6 6 2 2 2 1 1 0 1 1 3 1 1 0 3 1 1 1 1 1 28 1 1 1 2 1 1 1 1 1 1 1 2 3 1 1 1 1 1 1 4 1 1 1 10 21 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 1 2 1 1 1 1 1 1 1 1 2 2 1 1 1 2 1 2 1 1 2 2 1 4 2 1 4 2 2 0 1 1 1 1 1 11 1 23 0 1 0 0 0 |

Silver Flown

111 18 20 20 29 67 61 81 76 52 46 69 105 54 35 97 61 93 93 49 44 63 55 67 38 63 48 48 23 24 49 43 38 36 29 22 94 27 54 32 43 44 24 47 23 44 46 44 46 48 33 20 18 29 24 11 77 63 27 33 29 40 47 28 33 26 75 51 43 15 44 32 8 50 57 25 37 60 34 30 64 40 33 47 30 80 31 52 33 29 67 20 45 20 56 29 24 19 18 56 14 38 40 23 25 35 40 47 14 20 47 0 12 7 18 28 32 |

Silver Unflown

248 233 187 187 167 236 146 132 136 114 109 116 128 120 138 134 106 113 109 132 135 135 135 135 342 144 129 106 65 100 105 108 98 93 97 95 101 94 114 94 112 86 87 107 148 91 98 87 143 98 99 95 97 97 135 104 105 91 95 94 87 87 93 91 95 102 98 88 109 100 101 91 120 100 96 90 92 95 90 86 84 87 101 87 96 88 80 92 83 99 96 90 102 79 88 99 89 90 88 86 85 86 84 91 97 89 94 90 120 80 187 83 515 100 88 86 79 85 |